If the filtered material is more concentrated, it takes longer to press the filter to ensure the filtering effect. At the same time, if the filtered material is more difficult to filter, it also needs longer time to press the filter. However, if the concentration of the filtered material is lower, the filter press time can be shortened appropriately to save time.

In addition, the automatic plate and framefilter pressFaster than manual plate and frame filter presses because automatic plate and frame filter presses can automatically complete the processes of filtration and unloading, whereas manual plate and frame filter presses need to complete these processes manually.

It should be noted that in the process of filter press, it is necessary to pay close attention to the operating status and filtration effect of the equipment, and make adjustments and repairs according to the actual situation. At the same time, pay attention to safety in the operation process to avoid accidents.

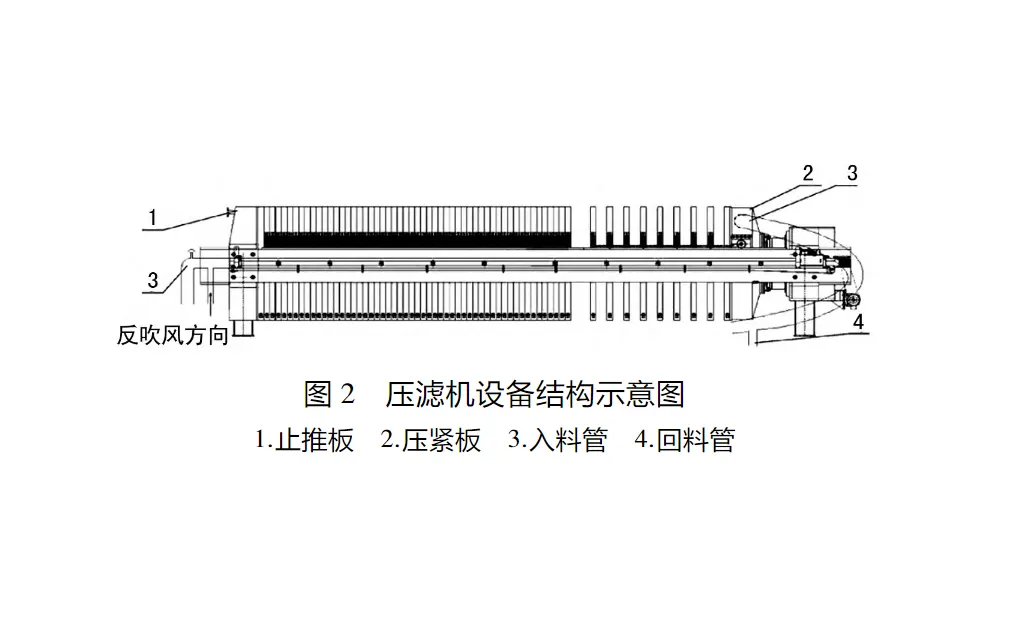

]]>1.1工作原理壓濾機主要由傳動部分、濾板部分、壓緊板部分、止推板部分、壓緊裝置(主要是液壓壓緊裝置)、液壓系統、電控系統及輔助部分組成。濾布裝在濾板兩面,在壓緊裝置作用下,濾板被壓緊在壓緊板和止推板l司.’每兩塊濾板之間形成一個封閉的濾室,當入料泵將物料打人濾室后,在入料壓力下,液相物通過濾布從濾液孔分離出來,固相物料留在濾室內逐漸形成濾餅,從而實現物料固液兩分離,入料泵停止給料后,松開壓緊板,卸掉濾餅,至此完成一個工作循環。

1.2XMZ型壓濾機的結構特點該型壓濾機與傳統壓濾機相比,具有較大的先進性:

(1)主梁結構采用雙廂式梁結構,該結構與傳統壓濾機(廂式梁式或板式梁)相比,抗彎、抗拉、抗扭強度高,重量輕,增強了主梁綜合性能。(2)濾板壓緊采用雙拖式柱塞缸液壓系統,使濾板壓緊時間降低一倍以上,大大提高了壓濾機的工作效率,傳統式壓濾機功率為5.5kw,本壓濾機功率為4kw,節能效果明顯,液壓馬達采用先進的擺線馬達,該馬達具有重量輕、體積小、運轉可靠等特點。

(3)本壓濾機控制系統采用PLC可編程控制器控制,同時,可根據要求配置文本顯示器,控制器和文本顯示器通過RS485進行通訊,通過文本顯示器顯示運行狀態、故障報警、工序時間、循環次數、壓力等多種數據,并且可以通過文本顯示器隨時設定油缸上下限,因此,可以直觀的、及時的掌握壓濾機的運行情況。2壓濾機的維護與保養(1)經常保持液壓系統整潔,嚴防雜物浸入而造成故障。

(2)壓濾過程中濾布要保持平整,不允許有褶皺,可視情況對濾布進行清洗。(3)經常檢查濾布,如有破漏,要及時更換、縫補。縫補濾布時,應將破漏處剪掉,然后縫補,以防止在密封面重疊,增加濾布厚度。

(4)定期向軸承注入潤滑脂,向傳動鏈條及軌道淋油,并清除污物。(5)定期給液壓系統補油、換油,并清洗濾油器,以保證液壓系統正常工作。(6)液壓系統油溫低于10°C時,可用加熱器提高油溫。

3壓濾機工作常見故障及原因分析、解決方法

3.1常見故障

(1)液壓系統故障。

(2)電氣系統故障。

(3)其他故障。

3.2故障分析

3.2.1液壓系統故障分析

(1)液壓系統流量不足的原因及處理辦法。

①油泵不排油,檢修油泵。

②順序閥調定壓力過低或閥芯在開口位置被卡住,檢修順序閥。

③濾油器堵塞,清洗濾油器。

④油箱油面太低,油泵吸空,應補油。

⑤液壓油粘度太大,吸油困難,應換油或提高油溫。

⑥泵內零件磨損嚴重,內泄大,壓力流量達不到額定值,檢修或更換油泵。

(2)系統壓力不足的原因及處理辦法。

①油泵故障,檢修油泵。

②溢流閥故障,調整或檢修溢流閥。

③有泄漏處應修好。

(3)開始松開濾板時,油缸油管發生沖擊振動,其原因是單向節流閥節流口過大,應關小單向節流閥節流口。

(4)壓緊板返回后,但不能直接轉換為拉板,除電氣故障外,主要是由于油缸內空氣未排凈,頭板前移,回程接近開關處于斷開狀態,處理方法是:擰松放氣螺塞,使油缸活塞往復運動,排盡空氣。

(5)拉板故障:首先是拉板壓力不正確,調整拉板壓力一般在3—4MPa,其次是拉板速度過快或過慢,對濾板沖擊過大或拉不動濾板,此時應調整調速閥,拉一塊濾板的時間大約為7—10秒。

3.2.2電氣故障分析發生電氣故障的原因是:導線松脫,接線錯了,元件動作不靈敏或損壞,螺栓松脫,零件碰壞或松動,電路或油路不對應,壓力繼電器調的不合適,可調整的元件未調整,導致內部斷線等。電氣故障的處理,要求電氣人員不僅要熟悉電氣原理圖、電氣元件的性能、還要了解液壓原理圖、壓濾機的控制及動力傳遞關系,同時,要了解壓濾機的工作狀態及工作過程。根據故障發生的時間,在哪一個工作過程中,在哪一個動作時發生的,判斷故障所在的區域。對于有些容易發生的故障,要先去檢查,可以加快排除故障的速度,如導線松脫、壓力繼電器調的不合適或損壞等。

3.2.3其他故障及分析

(1)噴漿產生的原因及處理方法。

①濾板邊框密封面夾人料餅,應洗清濾布;

②濾布損壞,達不到密封要求,更換濾布;

③入料濃度太低。適當提高入料濃度至5009/1。

(2)不成餅的原因及處理方法。

①入料粒度太小,應改進上道工序;

②入料粒度太小,物料粘性大,過濾性能差,應改變物料性質(用添加如絮凝劑等方法改善其過濾條件);

③人料濃度太低,成餅時間長,提高入料濃度。

(3)濾布損壞太快的原因入料粒度太大,應該進上道工序。(4)濾液管出黑水的原因是濾布破漏或濾布壓圈安裝不嚴密。

(5)濾板傾斜,其原因是濾板底部積存污泥太多,應清洗濾布。4結束語通過對壓濾機維護、保養及故障分析處理,大大提高壓濾機的使用效果,從而對洗煤廠的正常生產,提高洗煤效率,創收良好的經濟效益都起著重要作用。

壓濾機技術支持:188517-18517

]]>a power plantHow to reduce the water content of chamber filter press cakePhase I of the 2×630 MW unit project adopts limestone-gypsum wet full flue gas desulphurisation (FGD) with one furnace and one tower desulphurisation device, and the design desulphurisation efficiency is not less than 95 %. The desulphurisation wastewater treatment system adopts XAZ140/1250-U chamber filter press, and the specific technical parameters are as shown in Table 1.

The filter plate of chamber filter press is quadrangular, the filter cloth is in the concave filter plate on the projecting part, from 2 quadrangular filter plate to form a closed filter chamber. The main advantages of chamber filter press are low loss of feed, fast filtration speed, high temperature and pressure resistance, good sealing performance, uniform cake, low water content, basically applicable to all solid-liquid separation industries.

2 Working Principle of Chamber Filter Press When the chamber filter press is working, the hydraulic cylinder will press all the filter plates between the movable head plate and the fixed tail plate, so that the adjacent filter plates form a sealed filter chamber, and the slurry will be fed from the feeding holes of the fixed tail plate with a certain pressure. After all the chambers are filled with slurry, the filtration process begins, and the slurry is separated from the solids and liquids by the pressure of the feed pump. Solid particles remain in the filter chamber due to the blockage of the filter cloth, and the filtrate is discharged through the filter cloth along the drain on the filter plate. After a period of time, the filtrate no longer outflow, that is, the completion of the dewatering process. At this time, you can stop feeding, through the hydraulic manipulation system adjustment, the head plate back to the original position; by the filter plate moving device will be pulled open one after another; the filter cake rely on self-weight fall off, and is located in the lower part of the belt to transport away. In order to prevent the filter cloth eyelets from clogging, affecting the filtering effect, the filter cloth needs to be cleaned after unloading the cake. So far, the whole filtering process is completed.

3 Problems and Improvement of Vane Filter Presses

3.1 Problems in the actual application, affected by a variety of factors, the water content of the filter cake of the chamber filter press is relatively large, and the effect of filtration is not ideal. The large water content of the cake causes the cake to become sludge-like, attached to the filter cloth. Even if you use a shovel to poke, you can't drop the whole piece, and some of them even need to rinse the filter cloth before the next cycle, resulting in high labour intensity of the staff and long unloading time.

3.2 Problem analysis The lower the feed concentration, the higher the moisture of the filter cake. When the concentration of feed material is low, fine particles are very easy to enter the eyelets of the filter cloth, pass through, block or cover them, so that the eyelets of the filter cloth will be blocked soon. With the increase of feed concentration, there will be more particles close to or to the filter cloth eyelets, due to mutual interference, the vast majority of particles can not enter the eyelets and the formation of arches and bridges on the eyelets, which can make the filter holes in a longer period of time is not seriously blocked. With the filtration process, the average particle size of the filter cake formed on the surface of the filter cloth along the feeding direction from the outside to the inside gradually increases, and the cake resistance gradually decreases, so that the dewatering of the inner side of the cake (close to the side of the filter cloth) is affected, and this effect is gradually strengthened with the decrease in the concentration of the feeding material. After the study of the field conditions and a lot of tests, it was found that under the existing equipment, by adjusting the feed pressure, feed time, press [Abstract] A power plant chamber filter press in the application of the problem of large moisture content of the cake, the effect of filtration is not ideal. The problem was analysed, and it was confirmed that under the existing equipment and operating parameters, the filter press did not have the conditions to further reduce the water content of the cake. By increasing compressed air, the water content of the filter cake was reduced from 60 % to 10 %, which improved the sludge discharge efficiency. Parameters such as pressure and feed concentration can no longer effectively reduce the water content of the filter cake in the filter press, so it is necessary to propose an improvement programme.

3.3 Improvement programme In order to effectively reduce the water content of the filter cake in the chamber filter press, compressed air can be fed through the feed pipe after the feed of the filter press (unlike the diaphragm filter press). Compressed air automatic control device is added, and it can be switched directly through the DCS screen. The air and feed use the same inlet, when the feed is finished, close the feed valve and flush the feed pipe. After flushing, start conveying compressed air until no filtrate is discharged from the feed pipe to reach the state of equipment sludge discharge.

4 Conclusion

(1) Before using compressed air to reduce the water content of the filter cake, the filter cake in the filter press must be filled. If the cake is too thin, it will result in low water content of the cake at the inlet of compressed air, and the farther away it is, the higher the water content will be, and it will not even be able to play a role in reducing the water content.

(2) The time to pass into the compressed air needs to be determined according to the situation. Different materials, through the compressed air time is different. If the time is short, the water content of the cake is large; if the time is too long, it will cause the cake to dry out in contact with the filter cloth and attach to the filter cloth, increasing the workload.

(3) After adding compressed air, the material conveying pipeline needs to add a way of flushing water. Due to the influence of compressed air, the water content of the residual slurry in the feed pipe will also decrease, and further air-dry. After many times, the air-dried slurry will clog the pipe.

(4) After the transformation, after the actual operation verification, the effect of desliming has obvious improvement, the filter cake forming is more complete, the water content is as low as 10 %. the whole operation process can realise the continuous automatic cycle of mud, not only to improve the efficiency of the system mud, but also to reduce the frequency of manual on-site operation.

filter press(區別于帶式壓濾機,通常帶式壓濾機不宜陶瓷工業采用)按所用壓濾板(簡稱濾板)濾布的排列方式可大致區分為立式(濾板垂直疊壓后形成過濾室)Chamber Filter Press和臥式(濾板水平疊壓后形成過濾室)廂式壓濾機兩種結構形式。但因立式廂式壓濾機濾餅的剝離卸除操作比較困難等,因此,目前陶瓷工業等廠家廣泛應用的廂式壓濾機幾乎都是臥式廂式壓濾機(通常也簡稱為廂式壓濾機,除非另有說明)。同時,廂式壓濾機按濾板壓緊力的產生方式的差異又可區分為液壓壓緊型(由液壓油推動油缸柱塞產生壓緊濾板濾布的作用力)廂式壓濾機和機械作用壓緊型(如螺旋傳動機構等產生壓緊濾板濾布的作用力)廂式壓濾機。考慮到目前陶瓷泥漿的細度要求越來越細,那么陶瓷泥漿所需的壓濾脫水阻力比較大,同時也要求固體顆粒懸浮物型工業廢水及污水絮凝沉淀物壓濾脫水濃縮后獲得的污泥含水率越來越低,一方面,可節約人類賴以生存的有限的水資源;另一方面,可大幅度地降低運輸污泥至填埋場等運輸費用或降低污泥制作燒結磚的生產成本等。但因機械作用壓緊型廂式壓濾機的壓緊力通常較小,顯然經機械作用壓緊型廂式壓濾機處理后所得濾餅(陶瓷泥餅)或污泥的含水量通常偏高。所以說,機械作用壓緊型廂式壓濾機已逐漸被液壓壓緊型廂式壓濾機所取代。事實上,實踐生產經驗表明:廂式壓濾機框架的受力及其變形(剛性)的大小在一定范圍內嚴重影響廂式壓濾機的工作可靠性及其壓濾脫水效率的高低等。具體說來就是:如果壓濾機框架的剛性越大,其變形就越小,那么所得的濾餅(陶瓷泥餅)或污泥的含水量就越低,水資源的節約率就越高,生產成本就越低;反之,若壓濾機框架的剛性越小,其變形就越大,那么所得的濾餅(陶瓷泥餅)或污泥的含水量就越高,水資源的節約率就越低,生產成本就越高,還易造成廂式壓濾脫水操作過程中漏漿(也稱“跑漿”),嚴重時甚至造成廂式壓濾機后橫梁(也稱尾板)的斷裂等安全生產事故。所以,積極研究和探討廂式壓濾機框架的受力分析及其變形的大小,推導出其強度和剛度的設計計算或校核公式,據此合理地設計廂式壓濾機框架的強度和剛度,能最大限度地提高廂式壓濾機的工作可靠性及壓濾脫水效率等。

壓濾機的構造

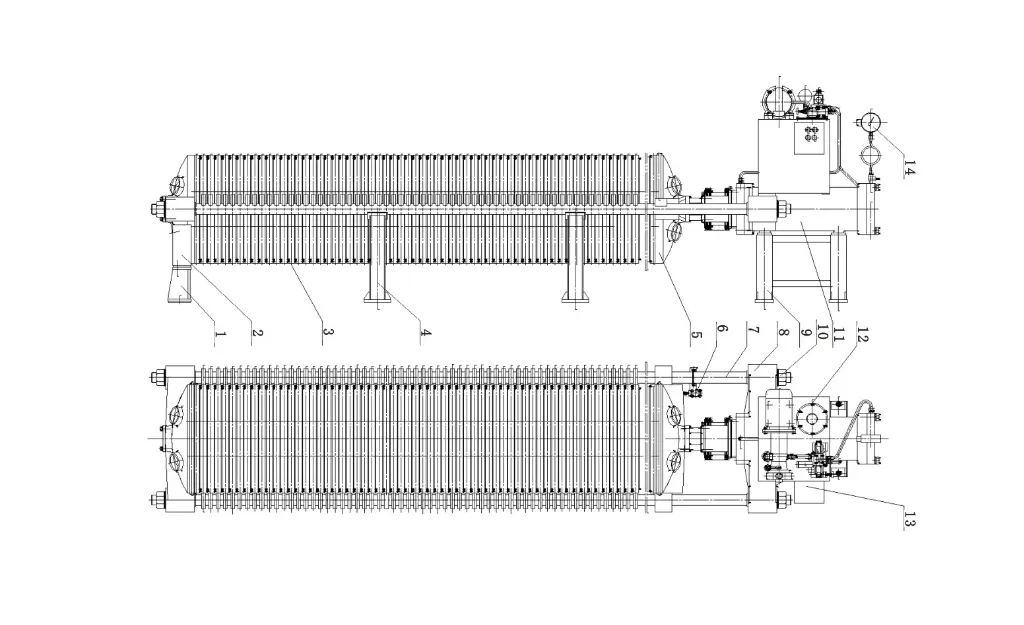

液壓壓緊型廂式壓濾機的結構示意圖如圖1所示。液壓壓緊型廂式壓濾機是集機、電、液于一體的自動化程度較高的固液分離設備,它主要由主機部分、過濾部分、液壓部分和電氣控制部分等組成。

1-尾部支架2-后橫梁(尾板)3-濾板濾布4-支柱5-推壓板(頭板)6-行程開關7-拉桿(導軌)8-前橫梁9-頭部支架10-鎖緊螺母11-液壓油缸柱塞壓緊裝置12-液壓站13-電氣控制箱14—電接點力。

主機部分

液壓壓緊型廂式壓濾機通常利用頭部支架和尾部支架支承整臺設備的質量。尾部后橫梁(與濾板濾布接觸處安置有漏水收集溝槽,俗稱尾板、也稱止推板)和進漿管相連接,頭部前橫梁內安裝有液壓油缸柱塞壓緊裝置,頭部前橫梁與尾部后橫梁兩側由拉桿(工作時,因濾板在拉桿上需縱向移動,所以拉桿也稱導桿)連接成一整體。考慮到廂式壓濾機工作時,拉桿既承受壓緊裝置所產生的壓緊力(縱向),又承受濾板濾布及陶瓷泥漿或固體顆粒懸浮物型工業廢水等過濾物的質量載荷(垂直方向),而且頭部前橫梁與尾部后橫梁通常相距較遠,因此,每側拉桿中間需設有一個或兩個支柱支承,以減少拉桿在垂直方向的彎曲變形等,確保液壓油缸柱塞帶動推壓板(與濾板濾布接觸處安置有漏水收集溝槽,也稱頭板)產生預定的壓緊濾板濾布的前進運動(俗稱緊榨)和退回卸餅(濾餅,陶瓷泥餅或污泥餅)運動(俗稱松榨),從而實現陶瓷泥漿或固體顆粒懸浮物型工業廢水等的壓濾脫水操作。由此可見,主機部分是壓濾機的基礎,用于支撐過濾機構及連接其他部件,通常由前橫梁、液壓油缸柱塞壓緊裝置、推壓板、后橫梁(俗稱尾板、也稱止推板)和拉桿等組成。液壓壓緊型廂式壓濾機表工作時,液壓油缸柱塞推動推壓板,將位于推壓板和止推板之間的濾板濾布依次壓緊,確保具有一定工作壓力(過濾推動力)的陶瓷泥漿或固體顆粒懸浮物型工業廢水或污水等在濾板濾布所形成的濾室內完成加壓過濾脫水操作而獲得含水率為25%左右的濾餅、廢渣或污泥等。

過濾部分

過濾部分主要是由濾板和濾布(也稱過濾布)等組成。濾板是中間有圓孔(待過濾漿料的通道)兩端內凹且具有許多相互連通的排水溝槽的圓形盤狀零件。其頂部制有濾布托架,便于安裝濾布。濾板兩側部制有支撐耳,可通過支撐耳垂直支承在兩側導桿上。

由于鑄鐵濾板的鑄造性能和機械切削加工性能良好,加工后表面噴塑處理后即可適用于陶瓷泥漿或固體顆粒懸浮物型工業廢水等壓濾脫水操作。但鑄鐵濾板的材料消耗大、質量大,人工拉開濾板卸餅(濾餅,陶瓷泥餅或污泥餅)時勞動強度大;此外,為了確保濾布免遭鑄鐵濾板排水溝槽的劃傷等損害,鑄鐵濾板兩側表面的排水溝槽表面須安裝(覆蓋)多孔的鋁質薄圓板(俗稱濾水板)。即便如此,壓濾脫水操作時,濾布仍會擠入鋁質濾水板的濾水孔中而損壞。總之,采用鑄鐵濾板壓濾脫水操作時,濾布的破損率較高,壓濾脫水操作生產成本較高。隨著科學技術的發展,鑄鐵濾板已逐漸被塑料濾板所取代,所以說,目前陶瓷工業或固體懸浮物型工業廢水等廣泛應用的廂式壓濾機大多數是采用塑料濾板進行壓濾脫水操作的。目前,塑料濾板的常用材質主要是聚乙烯、聚丙烯、增強聚丙烯、填充聚四氟乙烯、尼龍、聚甲醛和超高分子量聚乙烯等。因超高分子量聚乙烯是一種新型高效節能材料,具有耐壓性能好、耐磨性能好、耐熱性能好、耐腐蝕、抗沖擊、質量輕、防粘接性能好、易于壓注成形和機械切削加工性能良好等優點,并且使用壽命長(通常為聚丙烯濾板的4~6倍,鑄鐵濾板的3~9倍)及價格適中。同時,考慮到目前陶瓷泥漿的細度要求越來越細,而生產企業要求所得污泥的含水率也越來越低,那么陶瓷泥漿或固體顆粒懸浮物型工業廢水及污水等所需的過濾脫水阻力大,要求塑料濾板應具有較高的耐壓和耐磨性能等。由此可見,超高分子量聚乙烯塑料濾板是目前陶瓷工業或固體懸浮物型工業廢水及污水等廂式壓濾機的最佳選擇。濾布屬于機織物,是由經、緯兩系統紗線在織機上相互交織而成的織物。

濾布又是一種過濾介質,通常由合成纖維制成。合成纖維是化學纖維中的一類,它是利用煤、石油和天然氣等為原料,經提煉和化學合成作用而制成,包括:腈綸、滌綸、錦綸、維綸、氯綸及尼龍等,它們不僅具有不易發霉、不易被蟲蛀、質地輕、耐磨、耐酸堿、表面光潔及過濾后形成的濾餅剝離性好等特點,而且還具有抗拉、抗彎、抗磨等物理機械強度高及化學穩定性、熱穩定性好等優點,因此合成纖維濾布是目前過濾行業中應用最為廣泛的。同時,考慮到濾布的選用和使用對物料(漿料)的過濾效果具有決定性的作用,所以說,選用濾布時須根據過濾漿料的pH值、固含量的多少、固體微粒物的粒徑等因素選用適宜材質和適宜孔徑的高強度優質濾布,這樣可確保獲得較低的過濾成本和較高的過濾效率。具體包括以下幾方面:

1)濾布應經久耐用。

2)濾布應具有良好的化學穩定性和熱穩定性。

3)濾布應具有較高的物理機械強度。不管過濾漿料的多寡或密度的大小如何變化,濾布應能從頭到尾保持恒定的過濾速度,為達到這一目標,濾布必須具有較高的耐壓強度及耐磨強度等。

4)濾布制作前應先下水再晾干,待濾布縮水后再制作。制作時,濾布的開孔直徑應與濾板孔徑相等并且同心,然后通過兩側的銅質空心螺釘、銅質空心螺母(軸心是進漿通道)將濾布壓緊在濾板兩側的表面上。同時還要求濾布應能在給定的時期內保持恒定的過濾速度,如果過濾一開始,濾布的毛細孔就堵塞了,當然就達不到過濾的目的,濾布應該從始到終保持恒定的過濾速度。

5)要求濾布在形成濾餅之后,還能成為過濾介質而起著過濾的作用,即形成濾餅的剝離性能良好。

6)濾布不應在使用過程中發生收縮變化或膨脹變化等。一般說來,濾布毛細孔堵塞的原因主要是在于組成濾布的纖維本身在使用過程中發生收縮變化或膨脹變化等。7)移動濾板剝離卸除濾餅時,用力應均勻適當,不得沖擊碰撞等,以免損壞濾扳密封面及濾扳手把等。通常濾布使用一段時間后會變硬或發生毛細孔的堵塞等現象,需采用適宜的洗滌方法,如:采用相應低濃度的弱酸弱堿液進行中和清洗,可以使其恢復到足以繼續使用的程度,否則須及時更換濾布。

液壓部分

液壓部分主要是指液壓站,它是驅動液壓油缸柱塞壓緊裝置產生預定的運動實現壓緊各濾板濾布的動力裝置。主要由三相異步電動機、聯軸器、軸向柱塞泵(高壓油泵的一種)、三位四通電磁換向閥、溢流閥、液控單向閥、濾油器、油路塊(俗稱集成塊)、油箱、壓力表、壓力表開關和油壓管路等組成。

電氣控制部分

電氣控制部分是整個系統的控制中心,在電磁換向閥、行程開關及電接點壓力表的共同作用下,實現液壓油缸柱塞的“前進”、“后退”和“停止”等動作。同時,由于液壓傳動裝置不可避免地存在液壓密封件的磨損、液壓油的污染及液壓油的泄漏等缺陷,會造成濾板濾布壓緊力的降低,一旦液壓缸內油液壓力(嚴格地說,應為壓強)降低至某一預定值后,電接點壓力表立即發訊,迅速起動油泵驅動電機,再次向液壓油缸工作腔供油(俗稱灌油),確保濾板濾布壓緊力在一定范圍內大致恒定不變。否則,就會“漏漿”,污染生產環境,不利于生產環保。此外,其還具有欠電壓、過電壓和過電流保護等功能。

]]>

某公司是年產 25?萬噸(2?套系統)的鋅冶煉企業,其采用“火法+濕法”的煉鋅工藝。濕法鋅冶煉系統中,壓濾機是實現固液分離的主要設備。河南豫光鋅業目前擁有箱式Plate and frame filter press約 90?臺, 由于硫酸鋅極易結晶的特性,設備使用一段時間后,濾板表面會附著一層結晶,同時會出現濾道堵塞,既影響Filter Press Plate過濾效果,又造成濾板承受壓力增大,導致濾板損壞率居高不下,嚴重制約生產。因此,必須采取一些措施來優化濾板的操作、保養和清理方法,減少表面結晶,延長濾板使用壽命,降低生產消耗,保證生產連續穩定勢在必行。

影響濾板壽命的因素分析

某公司一套系統每年更換濾板 490?張,費用 47.6?萬元,結合多年的統計分析,造成濾板消耗量居高不下的主要原因為:

濾液中的硅酸鹽、鐵酸鹽與硫酸鋅結晶附著在濾板表面,形成附著力較強的膠狀物,因濾板表面特殊的晶粒結構,導致濾板清理困難、嚴重影響使用壽命;部分壓濾機進口壓力表的損壞,無法準確觀測壓濾機進料時的工作壓力,且單塊濾板結晶狀況不同,導致生產過程中承壓不等,存在進料壓力大于濾板的承受壓力的情況,從而影響濾板使用壽命;實際生產中,Filter Press Plate沒有按周期進行定期清理,或清理不徹底。濾道和濾板表面結晶有殘留,造成濾板破損;實際生產過程中,由于壓濾機存在跑渾現象,濾板兩側出現壓力不等,從而造成濾板損壞。

周期性對調不同工礦條件的濾板

凈液車間各工序因工藝操作的差異性,一段凈化槽工藝控制溫度:55-65℃,最佳溫度保持在 60℃。二段凈化槽工藝控制溫度在 85-92℃,最佳溫度保持在 90℃,溫度較高。同時,為降低濾板結晶,二段壓濾在壓濾機卸完渣后,通過壓濾機輸送廢液來清洗濾板表面附著的膠狀物,效果較明顯,濾板使用壽命延長。結合凈液工段實際生產情況及“就近方便”的原則:用一段凈化 1#-7#共七臺壓濾機濾板與二段凈化 8-10#三臺對調(其中11#-13#壓濾機與原壓濾機濾板尺寸不符)。根據生產和多次效果驗證,探索總結出濾板倒換表(見表 1)

表 1 凈液濾板周期倒換表

| 第 1周 | 第2周 | 第 3周 | 第4周 | 第5周 | 第6周 | 第 7周 | |

| 對調序號 | 1#與

8#對調 |

2#與

9#對調 |

3#與

10#對調 |

4#與

8#對調 |

5#與

9#對調 |

6#與

10#對調 |

7#與

8#對調 |

| 對調周期 | 二段壓濾機 3 周一輪 | ||||||

| 一段壓濾機 7 周一輪 | |||||||

經實際驗證結晶率降低 30%,濾板使用壽命提高 15%。目前此方法已推廣至氧化鋅浸出工序,通過對高酸壓濾機與低酸壓濾機、高酸還原壓濾機與低酸還原壓濾機濾板進行互換對調,效果明顯。

加強職工操作培訓

工段加強壓濾機培訓工作,針對壓濾機使用過程中的問題進行專項培訓,嚴格執行公司“三級巡檢”制度,及時發現壓濾機在運行過程中存在的問題,利用班前班后會組織相關人員對發現的問題進行溝通和解決。如職工通過觀察進料管道壓力表,保證進料壓力小于濾板承受壓力(規定壓濾機進料壓力:0.4-0.5Mpa, 達到該壓力停止進料,關閉進液閥門),發現濾液跑渾及時進行記錄,并在下次操作前更換濾布。通過培訓帶動管理和操作提升, 提高設備操作水平。

加強濾板保養

以往在對更換下的濾板在進行結晶清理時,濾板僅在酸液中浸泡一段時間,然后人工清理,堅硬結晶仍無法得到有效清理, 效果不佳。為解決結晶問題,使用高壓水槍清板,利用高壓水沖刷濾板表面結晶及濾道內雜物,效果較好。

打破常規濾板更換方法

改變新板、舊板混合使用的“常規更換”做法,推行濾板整臺更換的方法,杜絕新舊濾板混裝導致新濾板損壞。同時對更換下未損壞且外形完好的舊濾板進行清理、保養,與其它舊濾板一齊再次使用,充分延長其使用壽命。此方法不僅解決了新舊濾板混合使用造成設備整體精度降低,濾板損耗加快的問題,而且提高了設備的穩定性,促使公司產能不斷提升。

積極開展建標、對標和超標管理

積極響應公司“拉升產業標桿”的要求, 積極組織公司內部人員對使用、維護、保養、維修中好的做法和經驗進行總結,分類進行歸納和提高,并以此為標準。目前逐步形成從分廠、工段、班組人人有標準,時時對標準,勇于超標準的好習慣。

concluding remarks

filter press濾板使用方法的優化,有效的解決了濾板易結晶、不易清理、濾板損耗量大、壽命周期短的問題。避免了因濾板使用周期短、損耗率高而對生產造成制約。解決了鋅冶煉工藝硫酸鋅溶液因極易結晶而導致濾板消耗大的行業頑疾,為同行業管理提升和降耗具有很好的參考價值。

The sealing surface of polymer filter plate is elastic contact with good sealing performance and high strength.

Applications:

It is widely used in metallurgy, chemical industry, printing and dyeing, ceramics, food, medicine, mining, coal washing and other industries.

Quality Assurance:

The goal is to ensure the quality of the product, using the system, all-round testing.

Reasonably priced:

With excellent products, reasonable price, to achieve the product increasebe on dutyObjective.

Honest co-operation:

Over the decades, we have earned a reputation for integrity and won the market.

Sales:181-181-000-11

Selection:188-517-18-517

Mailbox:suton@su-ton.com

]]>High pressure diaphragm filter plateMade of TPE high quality material, good toughness and long service life.

Applications:

It is widely used in metallurgy, chemical industry, printing and dyeing, ceramics, food, medicine, mining, coal washing and other industries.

Quality Assurance:

The goal is to ensure the quality of the product, using the system, all-round testing.

Reasonably priced:

With excellent products, reasonable price, to achieve the product increasebe on dutyObjective.

Honest co-operation:

Over the decades, we have earned a reputation for integrity and won the market.

Sales:181-181-000-11

Selection:188-517-18-517

Mailbox:suton@su-ton.com

]]>Polypropylene reinforced filter plates are modified with TPE elastomeric material for sealing and corrosion resistance.

Applications:

It is widely used in metallurgy, chemical industry, printing and dyeing, ceramics, food, medicine, mining, coal washing and other industries.

Quality Assurance:

The goal is to ensure the quality of the product, using the system, all-round testing.

Reasonably priced:

With excellent products, reasonable price, to achieve the product increasebe on dutyObjective.

Honest co-operation:

Over the decades, we have earned a reputation for integrity and won the market.

Sales:181-181-000-11

Selection:188-517-18-517

Mailbox:suton@su-ton.com

]]>High pressure diaphragm filter plateMade of TPE high quality material, good toughness and long service life.

Applications:

It is widely used in metallurgy, chemical industry, printing and dyeing, ceramics, food, medicine, mining, coal washing and other industries.

Quality Assurance:

The goal is to ensure the quality of the product, using the system, all-round testing.

Reasonably priced:

With excellent products, reasonable price, to achieve the product increasebe on dutyObjective.

Honest co-operation:

Over the decades, we have earned a reputation for integrity and won the market.

Sales:181-181-000-11

Selection:188-517-18-517

Mailbox:suton@su-ton.com

]]>High pressure diaphragm filter plateMade of TPE high quality material, good toughness and long service life.

Applications:

It is widely used in metallurgy, chemical industry, printing and dyeing, ceramics, food, medicine, mining, coal washing and other industries.

Quality Assurance:

The goal is to ensure the quality of the product, using the system, all-round testing.

Reasonably priced:

With excellent products, reasonable price, to achieve the product increasebe on dutyObjective.

Honest co-operation:

Over the decades, we have earned a reputation for integrity and won the market.

Sales:181-181-000-11

Selection:188-517-18-517

Mailbox:suton@su-ton.com

]]>