I. Introduction to the original process

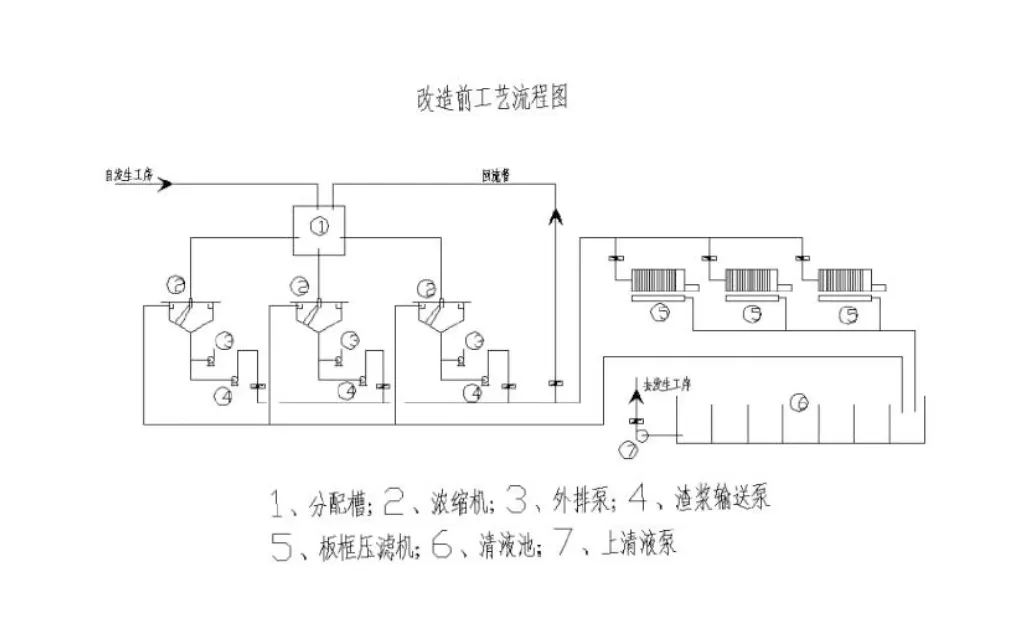

1. Process flow introduction by the acetylene section discharged from the solid content of less than 15% calcium carbide slurry, through the pipeline, ferry tank, distribution tank to the concentration pool, thickened by the thickening pool, the supernatant overflows to the ground brick pool overflows step by step to the clear pool for the occurrence of the section to continue to use, thickened solid content of more than 40% calcium carbide slurry slurry slurry pumps sent to the plate and frame filter press [2]. In the process of filter press, the calcium carbide slurry cake with water content less than 40% is transported out by car, and the filtrate flows to the clear night pool through the ferry, which is pumped to the generating process for use. The outlet of three thick slurry pumps converge into the slurry main pipe to be sent to the filter press, and the slurry main pipe flows back to the distribution tank on the top of the thickener. Our plant calcium carbide method of production of vinyl chloride design capacity of 120,000 tonnes / year, dry base calcium carbide slag production of 200,000 tonnes, calculated according to the water content of 40% annual production of wet calcium carbide slag 335,000 tonnes / year, 42 tonnes per hour production. The status quo of our equipment; 3 sets of 30m diameter thickener; each thickener has a slurry transfer pump totalling 3 sets;Plate and frame filter pressAdopt the filter press produced by Hebei Jingxian, open two and prepare one. When the slurry feed pressure of the plate and frame filter press is more than 0.7MPa, open the return valve, close the slurry feed valve, open the air valve to blow for 3 minutes and then close the air valve, and start unloading. The flow chart is as follows:

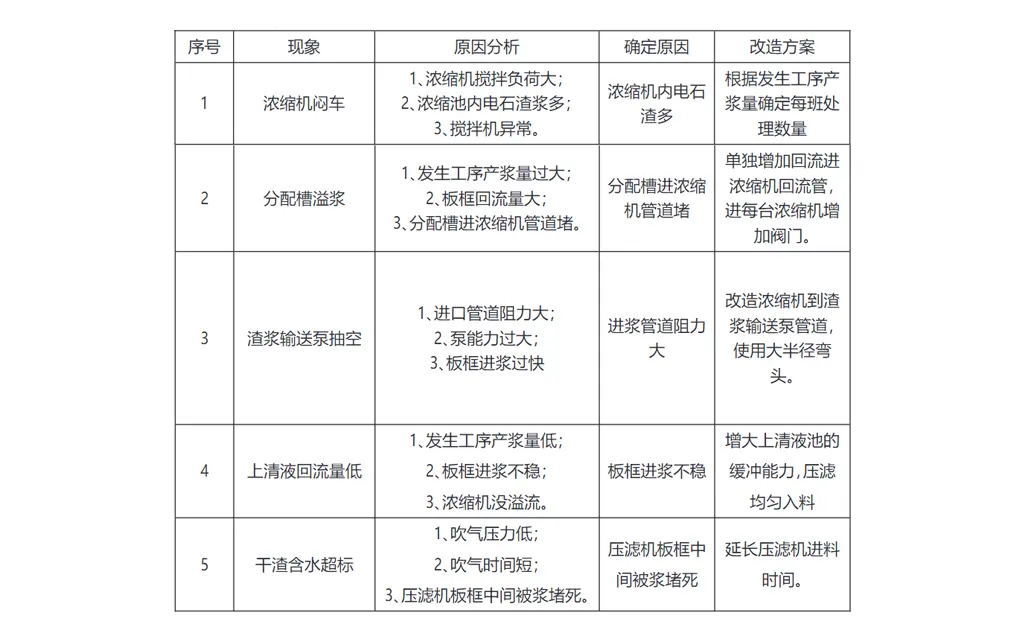

2. Problems through the operation of a period of time after the emergence of a number of problems, such as thickener bogging, distribution tank overflow, slurry transfer pump pump pumping, supernatant back to the low amount of water, dry slag water content exceeds the standard, but also often open the external discharge pumps, slag slurry to the grey stacks, and even affects the production of the positive output of the production. Second, the reasons and analysis due to my plant plate and frame filter press calcium carbide slag treatment process is based on the original device on the basis of the renovation project, part of the pipeline foundation and equipment to use the original, resulting in equipment layout, piping and so on, there are certain defects. So the plate and frame filter press process a driving problem frequently, directly affecting the normal production, the company organised part of the technical staff through careful analysis, the above problems were analysed one by one and took certain measures:

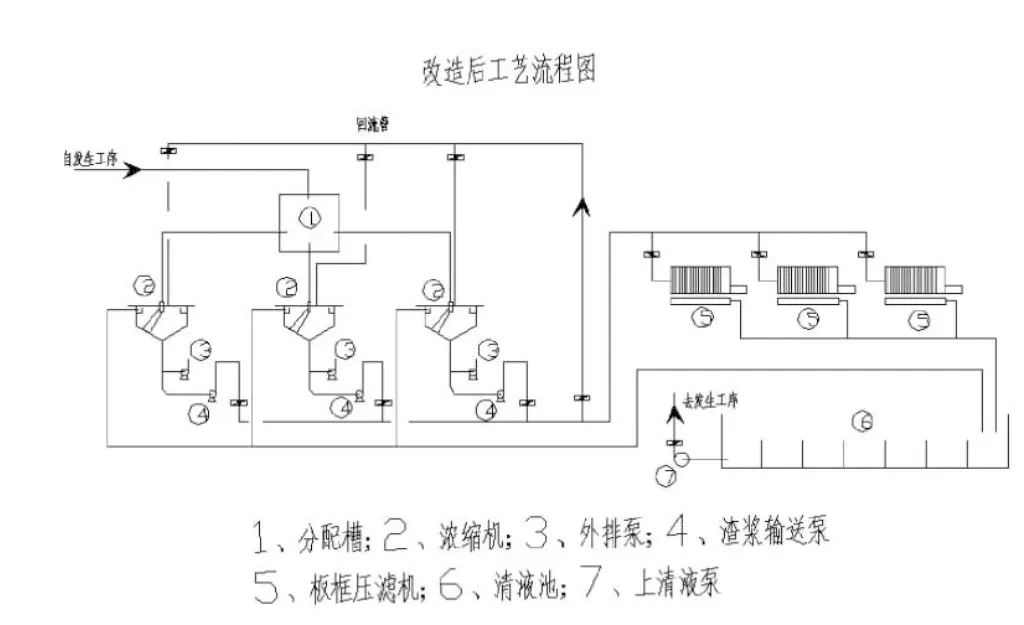

Third, after the transformation process through the technicians carefully analyze the problem of comprehensive analysis of the proposed transformation program: 1. operation program adjustment: production load is lower than 70% only use a thickener, the production load exceeds 70% when the use of a maximum of two thickeners; to ensure that the thickener level is low, there is no overflow; to improve the slagging frequency; filter press slurry into the control of the time in more than 10 minutes; blow time Control in more than 4 minutes; slurry reflux back to the use of a thickener; slurry transfer pump continuous operation, not stop the pump, to ensure that the thickener slurry cycle. 2. process transformation: reflux pipe re-piping, respectively, into the three thickeners, branching plus valve control, not into the distribution tank; thickener to the slurry conveyor pump pipeline thickening to 200 pipeline, elbow using 6 times the radius of elbows; blowing pipe changed to the upper inlet; supernatant Brick pool to reduce the height of the overflow weir, increase the amount of clear liquid buffer. The process flow diagram after transformation is as follows:

Conclusion Through the commissioning of plate and frame filter press device, it completely solves the problem of occupying land area and serious environmental pollution [4]. Every year for the company to save the occupation area cost 2 million yuan, save electric lime management more than 1 million yuan.

Disclaimer: The copyright of this article belongs to the original author and the original source.

Welcome to call us for consultation, technical exchange, and material experiment.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses