Filter press is a kind of mechanical equipment used for solid-liquid separation, which is widely used in environmental protection, chemical industry, food, medicine and other fields. In the use of filter presses, the pressure setting has an important impact on the separation effect and production capacity. This paper will focus on "how much pressure should be set in filter press?" This article will focus on the topic of "How much pressure should be set for filter press?" to discuss the principles and factors affecting the setting of filter press pressure, and how to reasonably select the pressure size.

I. Principle of setting pressure of filter press

Filter press pressure should be set according to the following principles:

1. Ensure the separation effect: In the process of filter press, sufficient pressure should be ensured to make the liquid penetrate through the material layer smoothly and achieve good solid-liquid separation effect.

2. Avoid excessive compression: Excessive pressure may lead to excessive compression of the material layer, which in turn reduces the rate of penetration and separation.

3. Consideration of equipment tolerance: Filter presses have limited pressure tolerance and should avoid exceeding their design pressure range.

4. Stable production: On the premise of ensuring separation effectiveness, the lowest possible pressure should be selected to ensure a stable production process.

II. Factors affecting the pressure setting of filter presses

The following factors need to be considered when determining filter press pressure:

1. Nature of material: The nature of the material such as particle size, density, moisture content, etc. will affect its response to pressure. For finer particles or materials with high moisture content, higher pressures may be required to achieve good separation.

2. Separation requirements: Different separation requirements require different pressures. If a higher separation efficiency is required, a higher pressure setting may be necessary.

3. Equipment model: Different models of filter presses have different pressure capacity and separation effect. The appropriate pressure size should be selected according to the equipment model and performance parameters.

4. Operating conditions: Actual operating conditions such as temperature, humidity, etc. will also have an effect on the pressure setting. In some cases, it may be necessary to adjust the pressure to suit specific operating conditions.

5. Safety factors: When setting the pressure, the safety features of the equipment must be considered. Excessive pressure may lead to equipment damage or accidents, so it should be ensured that the appropriate pressure level is selected on the premise of safety.

Third, how to reasonably select the size of the filter press pressure

The following measures are recommended in order to rationally select the pressure level of the filter press:

1. Understanding the nature of the material and separation requirements: when selecting a filter press, the nature of the material and separation requirements should be fully understood in order to determine the required pressure range.

2. Refer to the manual and performance parameters of the equipment: According to the manual and performance parameters provided by the equipment manufacturer, understand the maximum and minimum working pressure range of the selected filter press. Generally speaking, the maximum working pressure of the equipment should not exceed its rated value to ensure the safe operation of the equipment.

3. Conducting tests and adjustments: In practical applications, the pressure can be tested and adjusted according to the actual situation in order to find the optimal working pressure. By observing the separation effect, production capacity and equipment status and other indicators, the pressure parameters can be gradually optimised to improve the overall performance.

4. Maintenance and monitoring: In the course of use, the filter press should be regularly maintained and inspected to ensure its normal operation. The pressure changes of the equipment should be closely monitored, so that abnormalities can be detected in time and corresponding measures can be taken to prevent equipment damage or accidents.

5. Seek professional advice: In complex application scenarios or under specific operating conditions, professional advice and recommendations can be sought in order to more accurately select the right pressure level. By working with experienced engineers or technical experts, more targeted solutions and optimisation recommendations can be obtained.

The pressure setting of the filter press has an important influence on its separation effect and production capacity. When selecting and using a filter press, factors such as material properties, separation requirements, equipment type, working conditions and safety factors should be fully considered. By understanding the performance parameters of the equipment, conducting tests and adjustments, maintaining and monitoring, and seeking professional advice, the pressure of the filter press can be reasonably selected to improve its overall performance and ensure safe and stable operation.

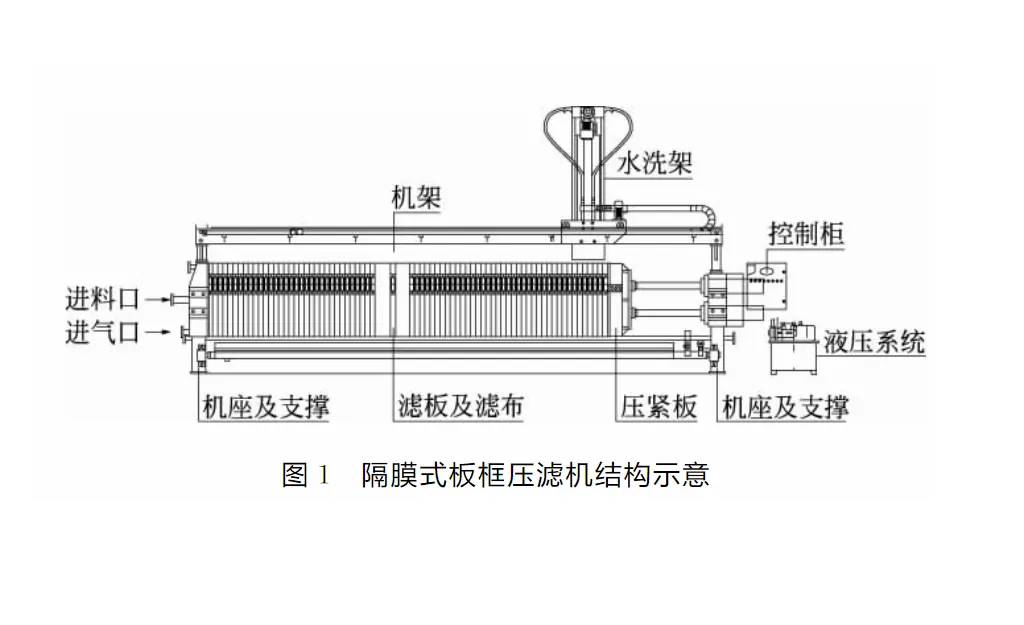

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses