【行業領先技術】蘇東壓濾機采用高強度濾板與智能控制系統,實現高效固液分離,過濾精度高,處理能力強,廣泛應用于化工、冶金、環保、食品等領域,滿足不同行業的過濾需求。

【節能耐用設計】優化結構設計,能耗降低30%,運行更穩定;選用耐磨抗腐蝕材料,設備壽命大幅延長,減少維護成本,為企業創造長期價值。

【智能自動化操作】配備PLC智能控制,一鍵啟停,實時監控運行狀態,操作簡便,安全可靠,大幅提升生產效率,降低人工成本。

【定制化服務】根據客戶需求提供個性化方案,支持濾板材質、過濾面積等靈活配置,確保每一臺壓濾機都能精準匹配生產要求。

選擇蘇東壓濾機,就是選擇高效、節能、省心的過濾專家!立即咨詢,獲取專屬解決方案!

關鍵詞:壓濾機、高效過濾設備、固液分離機、工業壓濾機、蘇東壓濾機廠家、智能壓濾機、化工過濾設備

]]>在當前工業過濾領域,設備的穩定性、效率與適配能力,直接影響企業的運行成本和產品品質。蘇東壓濾機正是基于多年市場實戰經驗,推出的高性能壓濾解決方案,廣泛服務于環保、制藥、化工、食品等多個行業,贏得了用戶一致好評。

作為專業壓濾設備供應商,蘇東壓濾機產品系列齊全,涵蓋手動壓濾機、小型實驗室壓濾機,到全自動智能隔膜壓濾系統。每一款產品都經過嚴格測試,確保長期運行無憂。

蘇東壓濾機的核心優勢:

? 過濾速度快,脫水率高:有效縮短工時,提升產能。

? 支持非標定制:根據不同行業需求,量身打造個性化壓濾方案。

? 結構堅固,耐腐耐磨:采用加厚鋼材與耐高溫濾板,適應各種復雜工況。

? 技術服務完善:提供遠程技術指導、視頻教學、配件快速發貨。

用戶在百度上搜索“蘇東壓濾機”,不只是為了看參數,更是為了找到一個能長期合作、解決實際問題的廠家。蘇東始終堅持以客戶為中心,從選型建議到售后服務,做到每一臺壓濾機都“買得放心,用得安心”。

如果您正在尋找一臺高性價比、適配性強的壓濾設備,歡迎了解蘇東壓濾機,我們愿為您的項目保駕護航。

]]>Zinc sulfide ores are the main source of zmc metal in the world,in which zinc generally exists in forms of sphalerite and marmatite.Currently,more than 80%of the zinc is produced by conventional zinc hydrometallurgical methods,including roasting,leaching and electrowinning processes[1,2】.During the roasting process,ZnS is converted to ZnO,but a significant fraction of ZnO reacts with the iron impurities to form zinc ferrite『3—51.Zinc ferrite is insoluble in mild acidic conditions,強Hs.a considerable amount of leaching residue will be produced in the subsequent leaching process f6,7].In addition,the leaching reaction rate decreases over time due to the decreasing acid concentration during the tradifional leaching process in stirred tank.Consequently,incomplete leaching will OCCur,thereby further increasing the generation of zinc leaching residue(ZLR),leading to a significant waste of resources and a high environmental risk【8,9】. The high demand for zinc has attracted the interest of industry to utilize the ZLR as a valuable secondary source[1].Hydrometallurgical processes are dely applied to recycle zinc from ZLR due to their significant advantages of lower capital and operating costs,as well as being less harmful to the environment[1,2].Currently, the most common hydrometallurgical process is to recover zinc from ZLR in a bath of hot concentrated sulfuric acid『10].A high extraction rate of zinc can be obtained using this process,but incomplete leaching still occurs due to the leaching in the stirred tank.Moreover, the hot concentrated acid leaching process involves a long reaction time f4—6¨and consumes an enormous amount of energy and sulfuric acid to process the 1arge amount of ZLRs obtained by thickening. More importantly,in most electrolytic zinc plants,the ZLRs containing water-soluble zinc with a content of less than 5%are directly discharged or heaped.causing a portion of the zinc losses.The water-soluble zinc can cause soil contamination,water pollution and several other serious environmental pollution through the leachate by rainfall[8,9].Therefore,finding a cost effective and environmental friendly process to recover zinc from ZLR remains a major challenge. The membrane filter press(MFP).which is a common machine on solid.1iquid separation,has advantages of low cost,high solid content and outstanding efficiency that has been widely used in various industries.In recent years.the washing functionof MFP has also been attracting attention for use in the titanium dioxide,sugar,pigment and electrolytic manganese metal industries[1卜14].LIU et al[14] recovered 50%of water-soluble manganese from an electrolytic manganese residue fEMR)via a MFP using water.This MFP—based water washing technology could be industrially applied because it solves the problem of ‘’water swelling”.which commonly occurs in previous water washing technologies[1 4,1 5].On the basis of the previous work of LIU et al[1 4],we attempted to wash the EMR via a MFP using anolyte.In 2009,the MFP—based technology on the leaching and recovery of manganese from EMR via a combination of anolyte washing with water washing was realized and resulted in a patent application being submitted(No.CN1 024700A) 『1 61.Note that several demonstrative operations have also been constructed in China based on this technology. However,the possibility of using this technology in the hydrometallurgical zinc process has never been investigated previously.If this technology could be used in electrolytic zinc plants,the thickening,pulping, second leaching,washing,filtering and pressing would be integrated and realized using a single MFR In addition,the leaching of zinc from ZLR in the form of spent electrolyte washing would be performed under constant acid concentration via a continuous flow of spent electrolyte. Hence.the feasibility of leaching and recovery of zinc from lcaching residue of zinc calcine based on MFP was investigated,combining spent electrolyte washing with flesh water washing.For this work.the uniformity of filter cakes.which is directly related to the leaching result,was examined.Based on this experimental result, the 1eaching and washing on extracting zinc from ZLR were subsequently studied.

1 Introduction

Zinc sulfide ores are the main source of zmc metal in the world,in which zinc generally exists in forms of sphalerite and marmatite.Currently,more than 80%of the zinc is produced by conventional zinc hydrometallurgical methods,including roasting,leaching and electrowinning processes[1,2】.During the roasting process,ZnS is converted to ZnO,but a significant fraction of ZnO reacts with the iron impurities to form zinc ferrite『3—51.Zinc ferrite is insoluble in mild acidic conditions,強Hs.a considerable amount of leaching residue will be produced in the subsequent leaching process f6,7].In addition,the leaching reaction rate decreases over time due to the decreasing acid concentration during the tradifional leaching process in stirred tank.Consequently,incomplete leaching will OCCur,thereby further increasing the generation of zinc leaching residue(ZLR),leading to a significant waste of resources and a high environmental risk【8,9】. The high demand for zinc has attracted the interest of industry to utilize the ZLR as a valuable secondary source[1].Hydrometallurgical processes are dely applied to recycle zinc from ZLR due to their significant advantages of lower capital and operating costs,as well as being less harmful to the environment[1,2].Currently, the most common hydrometallurgical process is to recover zinc from ZLR in a bath of hot concentrated sulfuric acid『10].A high extraction rate of zinc can be obtained using this process,but incomplete leaching still occurs due to the leaching in the stirred tank.Moreover, the hot concentrated acid leaching process involves a long reaction time f4—6¨and consumes an enormous amount of energy and sulfuric acid to process the 1arge amount of ZLRs obtained by thickening. More importantly,in most electrolytic zinc plants,the ZLRs containing water-soluble zinc with a content of less than 5%are directly discharged or heaped.causing a portion of the zinc losses.The water-soluble zinc can cause soil contamination,water pollution and several other serious environmental pollution through the leachate by rainfall[8,9].Therefore,finding a cost effective and environmental friendly process to recover zinc from ZLR remains a major challenge. The membrane filter press(MFP).which is a common machine on solid.1iquid separation,has advantages of low cost,high solid content and outstanding efficiency that has been widely used in various industries.In recent years.the washing functionof MFP has also been attracting attention for use in the titanium dioxide,sugar,pigment and electrolytic manganese metal industries[1卜14].LIU et al[14] recovered 50%of water-soluble manganese from an electrolytic manganese residue fEMR)via a MFP using water.This MFP—based water washing technology could be industrially applied because it solves the problem of ‘’water swelling”.which commonly occurs in previous water washing technologies[1 4,1 5].On the basis of the previous work of LIU et al[1 4],we attempted to wash the EMR via a MFP using anolyte.In 2009,the MFP—based technology on the leaching and recovery of manganese from EMR via a combination of anolyte washing with water washing was realized and resulted in a patent application being submitted(No.CN1 024700A) 『1 61.Note that several demonstrative operations have also been constructed in China based on this technology. However,the possibility of using this technology in the hydrometallurgical zinc process has never been investigated previously.If this technology could be used in electrolytic zinc plants,the thickening,pulping, second leaching,washing,filtering and pressing would be integrated and realized using a single MFR In addition,the leaching of zinc from ZLR in the form of spent electrolyte washing would be performed under constant acid concentration via a continuous flow of spent electrolyte. Hence.the feasibility of leaching and recovery of zinc from lcaching residue of zinc calcine based on MFP was investigated,combining spent electrolyte washing with flesh water washing.For this work.the uniformity of filter cakes.which is directly related to the leaching result,was examined.Based on this experimental result, the 1eaching and washing on extracting zinc from ZLR were subsequently studied.

2 Experimental 623

2.1 Materials The experimental study was performed using zinc calcine with a composition of 57%zinc.which was purchased from Hunan Province。 China. Spent electrolyte containing 1 60 g/L of H2S04 and 50 g/L of Zn”was used in all of the leaching experiments.Under all examined conditions.the zinc concentration was determined based on GB/T 14353.3-2010『17],and the hydrogen ion concen仃ation fH+、was measured based on GB 6498.2-2001『181.The membrane filter press (KM470)was from Beijing ZSC Solid—Liquid Separating Technology Co.,Ltd.(China),and the membrane plates (470 ml/l×470 mill)were from LENSER Filtration GmbH+Co.(Germany).

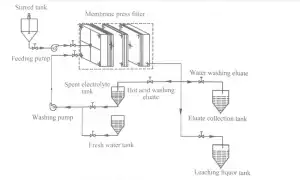

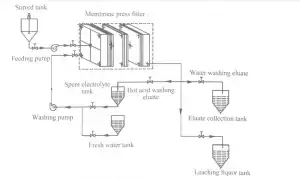

2.2 Experimental procedure The diagram of leaching and recovery of zinc from zinc calcine is presented in Fig.1.111e proper production process is described briefly as follows.1 1 leaching in stirred.tank reactor:Spent electrolyte or sulfuric acid was added to the crashed zinc calcine to leach zinc ions from the ores and to obtain the ZnS04-contained slurry.2、 filtration:the ZnS04-contained slurry was pumped into MFP through central feeding hole and filter pressed to obtain the filter cakes(i.e.,ZLR);next,the filtrate (1eaching liquor)entered the subsequent production process.3、Re.1eaching inⅣ【FP:Spent electrolyte at the desired temperature was pumped into the MFP and reacted with filter cakes to leach zinc again and simultaneously recover part of ZnS04.4)water washing: The filter cakes were washed again with flesh water to further recover ZnS04.5)pressing:Water with a pressureof 1 MPa was pumped into the membrane plates.which was maintained for 20 min to reduce the water content of filter cakes, and the pressed filter cakes were subsequently discharged from the MFP and transported to landfills.The eluate obtained from spent electrolyte washing and flesh water washing steps were collected and returned to spent electrolyte tank and eluate collection tank,respectively.

3 Results and discussion

3.1 Filter cake formation To obtain a high zinc ex仃action rate and recovery rate using an MFP.the most important step is to obtain uniform filter cakes.The particle size of zinc calcine and sedimentation time.which are directly involved with the width of the filter chambers,are the most important parameters regarding the uniformity of filter cake. Therefore,the particle sizes of zinc calcine,as well as the width of the filter chamber were firstly selected.The five—spot test(upper left,bottom left,center,upper right, bottom right)was used for estimating the uniformity of the filter cakes by measuring the zinc content and thickness of the cakes at these selected points. Through observation of the filter cakes formed in the MFP,it is found that triangle cakes were easily formed using raw zinc calcine.The particle size distribution of raw zinc calcines was measured and the corresponding result is presented in Table 1.The presence zinc calcine of large particle size inhibits the formation of uniform cakes due to its good settleability: thus,small size particles should be selected.Choosing the particle size of zinc calcine less than 106 gm仃、able 1 1。which could be obtained in actual production,a series of experiments regarding the filter cake formation were conducted.and the results are presented in Fig.2. From Fig.2,using zinc calcines with particle sizes less than 1 06 gm,the zinc content and filter cake thickness vary clearly at the five tested points when the filter chamber width is 40 mln,suggesting that the cake uniformity is poor under this condition,which might be due to long sedimentation time.When the filter chamber width is 30 lnnl.the cake uniformity is improved significantly relative to the chamber width of 40 nun. When the filter chamber width is 20 mm,the cake uniformity is similar to the results obtained as the chamber width is 30 mm.Thus.it can be clearly observed that the uniforlTl filter cakes could be formed by choosing the particle size of zinc calcine to be less than 1 06 Bm for filter chamber widths of 20 mm and 30 mill. As a result.the zinc calcines with particle size 1ess than 1 06 Bm were used in the following experiments.The processing capacity of MFP with 20 mm width chamber is 10wer than that with 30 toni width chamber.Therefore. combining the results of processing capacity and cake uniformity,the chamber width of 30 finn was selected in the following experiments.

3.2 Leaching of zinc from zinc calcine In this lcaching process.1 00 L of spent electrolyte solution was added to a 300 L stainless steel drum equipped with a variable speed stirrer and then stirred for approximately 1 h at a speed of 60 r/min.Next,the 1eaching solution was adjusted by adding zinc calcine or sulfate acid until the final Zn”concentration of electrolyte was in the range of 130-140 g/L and the final H2S04 concentration was in the range of l一2 g/L. Subsequently,the ZnS04-contained slurry was filtered using a MFE The analysis results of zinc calcine and ZLR are presented in 1’ables 2 and 3.respectively. As presented in Table 2.the grade of zinc calcine is 57.52%.in which ZnO approximately accounts for 90.06%of total zinc in mass.Table 3 indicates that in this process of leaching,most of the Zn0 is converted to ZnS04,resulting in the dramatic decrease of the content of ZnO.After solid-liquid separation using the MFP. many insoluble materials are concentrated in the residue. The content of zinc in the leaching residue is higher than 20%,causing the extraction rate of zinc in this process to be less than 90%.Analysis of ZLR indicates that zinc iS mainly presented in the forills of ZnFe204,ZnO and ZnS04,which in total account for uD to 80%of the zinc(Table 3).Thus,a secondary leaching process is required to recover the remaining zinc.

3.3 Leaching of zinc from ZLR In this leaching process,the zinc was extracted from ZLR obtained in Section 3.2 in the form of spent electrolyte washing using MFE To dissolve ZnFe204, strict leaching conditions,such as high temperature (above 90。C、and high concentration of acid solution (100—200 g/L),are required.Under hi。曲temperature and high acid concentration conditions,the extraction rate of zinc can increase to approximately 97%[19,20].To enable a comparison with the extraction rate obtained in the traditional route.the lcaching conditions in the present work are under a temperature in the range of 90 to 96 oC and an acid concentration in the range of 1 00 to 200 g/L.Becanse也e leaching residues of zinc calcine were fixed in the chamber of the MFP.the high reaction temperature condition was realized through heating of the spent electrolyte. Figure 3 shows the Zn”and H2S04 concentrations with leaching time under atemperature in the range of 90 to 96 oC during the leaching process based on MFE From Fig。3.the Zn”concentration is observed to obviously increase during the initial 5 min,followed by a decrease to 55璣after washing for 60 min and only a slight change around the level of 55 g/L in the following 30 min.Conversely’the H2S04 concentration obviously decreases during the initial 5 min.followed by an increase to 11 7 g/L after washing for 60 min and then slight changes around the level of 120 g/L in next 30 min. Based on these above results,it can be concluded that the violently reaction of the leaching residue with the hot spent electrolyte only lasts for approximately 60 min. The analysis result of the residue after hot concentrated acid leaching for 90 min is presented in T2lble 4.Clearlv. the zinc content in the residue reduces significantly from over 20%(Table 3)to less than 1 0%(Table 41.As a consequence,the zinc extraction rate 1ncreases to 97%. 碭Hs.this result obviously demonstrates that using a MFP as a leaching reactor could not only ensure a high extraction rate but also reduce the leaching time compared with the traditional hot concentrated acid leaching.The short leaching time using a MFP might be due to the constant reaction conditions of high temperature and high acid concentration during the whole process when using a MFE Based on the above results.additional experiments on the leaching of zinc from ZLR were also conducted under low temperatures,such as at 30 oC,60 to 70 oC,70 to 80 oC and 80 to 90 oC.to reduce the energy consumption further.The corresponding results are presented in Fig.4. The zinc extraction rate at 30 oC is 92.67%.and increases to 94.95%at 60 to 70。C.When the 1eaching temperature is further increased to 80 to 90。C.the ex仃action ratio increases to 95.56%.The temperature of spent electrolyte has an obvious effect on t11e zinc extraction ratio.High zinc extraction could be obtained by increasing the temperature of leaching,which is consistent wim the results of Ref.f191.Under Iow temperatures,the energy consumption is lower,the extraction ratio can not reach the traditional result of 97%.In conelusion.the hot acid leaching only at 90 to 96 oC or above can achieve the ideal result(i.e.,more than 97%、.

3.4 Recovery of water-soluble zinc

The water-soluble zinc approximately accounts for 3%of the total zinc in the residue after hot acidleaching with MFP(Table 41.To recover this part of the zinc.the leaching residue was further washed with Water. Figure 5 shows that both the Zn2+and H,S04 concentrations of eluate decrease with increasing washing time.especially in the initial 5 min.These results indicate that Zn”and H,S04 in the zinc residue could be quickly washed out by Water using the MFP. After washing for 25 min,the final Znz+and H2S04 concentrations of eluate decrease to 0.05嘰and 1.25 g/L.respectively. The final residue obtained after being washed and pressed merely contains 6%of zinc.in which the water-soluble zinc only accounts for 0.07%(Table 5), suggesting that the majority of water-soluble zinc is recovered during the water washing process.Compared with the traditional hot concentrated acid leaching process,the water-soluble zinc lost in the leaching residue iS very 10W. 3.5 Washing uniformity To estimate the washing results,the washing uniformity of MFP was examined by measuring.both the total zinc and the water-soluble zinc contents in the final residue.As presented in Rlble 6.both the total zinc and the water-soluble zinc contents change slightly at five selected points(upper left,bottom left,center,upper right,and bottom right)in the residue,indicating that the hot spent electrolyte and water washing are quite uniforiil.Therefore.the zinc that can be extracted in zinc calcine and the Water-soluble zinc that can be recovered in the residue are completely extracted and recovered by USing the MFP.

4 Conclusions

1】The use of a MFP is found to be completely feasible and effective to 1each and recover zinc from leaching residues ofzinc calcine.

2】The zinc calcines with particle size of less than 1 06 gm and MFP chambers with a width of 30 I/IlTI are proper for establishing unifornl filter cakes to obtain acceptable leaching and recovery results.

2 Experimental 623

2.1 Materials The experimental study was performed using zinc calcine with a composition of 57%zinc.which was purchased from Hunan Province。 China. Spent electrolyte containing 1 60 g/L of H2S04 and 50 g/L of Zn”was used in all of the leaching experiments.Under all examined conditions.the zinc concentration was determined based on GB/T 14353.3-2010『17],and the hydrogen ion concen仃ation fH+、was measured based on GB 6498.2-2001『181.The membrane filter press (KM470)was from Beijing ZSC Solid—Liquid Separating Technology Co.,Ltd.(China),and the membrane plates (470 ml/l×470 mill)were from LENSER Filtration GmbH+Co.(Germany).

2.2 Experimental procedure The diagram of leaching and recovery of zinc from zinc calcine is presented in Fig.1.111e proper production process is described briefly as follows.1 1 leaching in stirred.tank reactor:Spent electrolyte or sulfuric acid was added to the crashed zinc calcine to leach zinc ions from the ores and to obtain the ZnS04-contained slurry.2、 filtration:the ZnS04-contained slurry was pumped into MFP through central feeding hole and filter pressed to obtain the filter cakes(i.e.,ZLR);next,the filtrate (1eaching liquor)entered the subsequent production process.3、Re.1eaching inⅣ【FP:Spent electrolyte at the desired temperature was pumped into the MFP and reacted with filter cakes to leach zinc again and simultaneously recover part of ZnS04.4)water washing: The filter cakes were washed again with flesh water to further recover ZnS04.5)pressing:Water with a pressureof 1 MPa was pumped into the membrane plates.which was maintained for 20 min to reduce the water content of filter cakes, and the pressed filter cakes were subsequently discharged from the MFP and transported to landfills.The eluate obtained from spent electrolyte washing and flesh water washing steps were collected and returned to spent electrolyte tank and eluate collection tank,respectively.

3 Results and discussion

3.1 Filter cake formation To obtain a high zinc ex仃action rate and recovery rate using an MFP.the most important step is to obtain uniform filter cakes.The particle size of zinc calcine and sedimentation time.which are directly involved with the width of the filter chambers,are the most important parameters regarding the uniformity of filter cake. Therefore,the particle sizes of zinc calcine,as well as the width of the filter chamber were firstly selected.The five—spot test(upper left,bottom left,center,upper right, bottom right)was used for estimating the uniformity of the filter cakes by measuring the zinc content and thickness of the cakes at these selected points. Through observation of the filter cakes formed in the MFP,it is found that triangle cakes were easily formed using raw zinc calcine.The particle size distribution of raw zinc calcines was measured and the corresponding result is presented in Table 1.The presence zinc calcine of large particle size inhibits the formation of uniform cakes due to its good settleability: thus,small size particles should be selected.Choosing the particle size of zinc calcine less than 106 gm仃、able 1 1。which could be obtained in actual production,a series of experiments regarding the filter cake formation were conducted.and the results are presented in Fig.2. From Fig.2,using zinc calcines with particle sizes less than 1 06 gm,the zinc content and filter cake thickness vary clearly at the five tested points when the filter chamber width is 40 mln,suggesting that the cake uniformity is poor under this condition,which might be due to long sedimentation time.When the filter chamber width is 30 lnnl.the cake uniformity is improved significantly relative to the chamber width of 40 nun. When the filter chamber width is 20 mm,the cake uniformity is similar to the results obtained as the chamber width is 30 mm.Thus.it can be clearly observed that the uniforlTl filter cakes could be formed by choosing the particle size of zinc calcine to be less than 1 06 Bm for filter chamber widths of 20 mm and 30 mill. As a result.the zinc calcines with particle size 1ess than 1 06 Bm were used in the following experiments.The processing capacity of MFP with 20 mm width chamber is 10wer than that with 30 toni width chamber.Therefore. combining the results of processing capacity and cake uniformity,the chamber width of 30 finn was selected in the following experiments.

3.2 Leaching of zinc from zinc calcine In this lcaching process.1 00 L of spent electrolyte solution was added to a 300 L stainless steel drum equipped with a variable speed stirrer and then stirred for approximately 1 h at a speed of 60 r/min.Next,the 1eaching solution was adjusted by adding zinc calcine or sulfate acid until the final Zn”concentration of electrolyte was in the range of 130-140 g/L and the final H2S04 concentration was in the range of l一2 g/L. Subsequently,the ZnS04-contained slurry was filtered using a MFE The analysis results of zinc calcine and ZLR are presented in 1’ables 2 and 3.respectively. As presented in Table 2.the grade of zinc calcine is 57.52%.in which ZnO approximately accounts for 90.06%of total zinc in mass.Table 3 indicates that in this process of leaching,most of the Zn0 is converted to ZnS04,resulting in the dramatic decrease of the content of ZnO.After solid-liquid separation using the MFP. many insoluble materials are concentrated in the residue. The content of zinc in the leaching residue is higher than 20%,causing the extraction rate of zinc in this process to be less than 90%.Analysis of ZLR indicates that zinc iS mainly presented in the forills of ZnFe204,ZnO and ZnS04,which in total account for uD to 80%of the zinc(Table 3).Thus,a secondary leaching process is required to recover the remaining zinc.

3.3 Leaching of zinc from ZLR In this leaching process,the zinc was extracted from ZLR obtained in Section 3.2 in the form of spent electrolyte washing using MFE To dissolve ZnFe204, strict leaching conditions,such as high temperature (above 90。C、and high concentration of acid solution (100—200 g/L),are required.Under hi。曲temperature and high acid concentration conditions,the extraction rate of zinc can increase to approximately 97%[19,20].To enable a comparison with the extraction rate obtained in the traditional route.the lcaching conditions in the present work are under a temperature in the range of 90 to 96 oC and an acid concentration in the range of 1 00 to 200 g/L.Becanse也e leaching residues of zinc calcine were fixed in the chamber of the MFP.the high reaction temperature condition was realized through heating of the spent electrolyte. Figure 3 shows the Zn”and H2S04 concentrations with leaching time under atemperature in the range of 90 to 96 oC during the leaching process based on MFE From Fig。3.the Zn”concentration is observed to obviously increase during the initial 5 min,followed by a decrease to 55璣after washing for 60 min and only a slight change around the level of 55 g/L in the following 30 min.Conversely’the H2S04 concentration obviously decreases during the initial 5 min.followed by an increase to 11 7 g/L after washing for 60 min and then slight changes around the level of 120 g/L in next 30 min. Based on these above results,it can be concluded that the violently reaction of the leaching residue with the hot spent electrolyte only lasts for approximately 60 min. The analysis result of the residue after hot concentrated acid leaching for 90 min is presented in T2lble 4.Clearlv. the zinc content in the residue reduces significantly from over 20%(Table 3)to less than 1 0%(Table 41.As a consequence,the zinc extraction rate 1ncreases to 97%. 碭Hs.this result obviously demonstrates that using a MFP as a leaching reactor could not only ensure a high extraction rate but also reduce the leaching time compared with the traditional hot concentrated acid leaching.The short leaching time using a MFP might be due to the constant reaction conditions of high temperature and high acid concentration during the whole process when using a MFE Based on the above results.additional experiments on the leaching of zinc from ZLR were also conducted under low temperatures,such as at 30 oC,60 to 70 oC,70 to 80 oC and 80 to 90 oC.to reduce the energy consumption further.The corresponding results are presented in Fig.4. The zinc extraction rate at 30 oC is 92.67%.and increases to 94.95%at 60 to 70。C.When the 1eaching temperature is further increased to 80 to 90。C.the ex仃action ratio increases to 95.56%.The temperature of spent electrolyte has an obvious effect on t11e zinc extraction ratio.High zinc extraction could be obtained by increasing the temperature of leaching,which is consistent wim the results of Ref.f191.Under Iow temperatures,the energy consumption is lower,the extraction ratio can not reach the traditional result of 97%.In conelusion.the hot acid leaching only at 90 to 96 oC or above can achieve the ideal result(i.e.,more than 97%、.

3.4 Recovery of water-soluble zinc

The water-soluble zinc approximately accounts for 3%of the total zinc in the residue after hot acidleaching with MFP(Table 41.To recover this part of the zinc.the leaching residue was further washed with Water. Figure 5 shows that both the Zn2+and H,S04 concentrations of eluate decrease with increasing washing time.especially in the initial 5 min.These results indicate that Zn”and H,S04 in the zinc residue could be quickly washed out by Water using the MFP. After washing for 25 min,the final Znz+and H2S04 concentrations of eluate decrease to 0.05嘰and 1.25 g/L.respectively. The final residue obtained after being washed and pressed merely contains 6%of zinc.in which the water-soluble zinc only accounts for 0.07%(Table 5), suggesting that the majority of water-soluble zinc is recovered during the water washing process.Compared with the traditional hot concentrated acid leaching process,the water-soluble zinc lost in the leaching residue iS very 10W. 3.5 Washing uniformity To estimate the washing results,the washing uniformity of MFP was examined by measuring.both the total zinc and the water-soluble zinc contents in the final residue.As presented in Rlble 6.both the total zinc and the water-soluble zinc contents change slightly at five selected points(upper left,bottom left,center,upper right,and bottom right)in the residue,indicating that the hot spent electrolyte and water washing are quite uniforiil.Therefore.the zinc that can be extracted in zinc calcine and the Water-soluble zinc that can be recovered in the residue are completely extracted and recovered by USing the MFP.

4 Conclusions

1】The use of a MFP is found to be completely feasible and effective to 1each and recover zinc from leaching residues ofzinc calcine.

2】The zinc calcines with particle size of less than 1 06 gm and MFP chambers with a width of 30 I/IlTI are proper for establishing unifornl filter cakes to obtain acceptable leaching and recovery results.

]]>

一、蘇東壓濾機的含義

蘇東壓濾機,,總部位于中國江蘇泰州。作為國內壓濾機行業的領軍企業,蘇東壓濾機專注于壓濾機、壓濾機配件以及濾板加工的銷售與服務。經過三十多年的發展,蘇東壓濾機已成為國內過濾行業的佼佼者,產品遠銷全球多個國家和地區。

二、蘇東壓濾機的技術特點

1. 高效過濾:蘇東壓濾機采用先進的過濾技術,能夠實現高效過濾,提高過濾效率,降低能耗。其獨特的濾布設計,可有效攔截液體中的雜質,滿足各種過濾需求。

2. 自動化程度高:蘇東壓濾機具備高度自動化的操作系統,減少了人工干預,降低了人工成本。自動化操作也提高了過濾過程的穩定性和可靠性。

3. 耐腐蝕性強:蘇東壓濾機的主要部件采用耐腐蝕性強的材料制造,能夠在各種惡劣的工業環境中穩定運行,有效延長了設備的使用壽命。

4. 易于維護:蘇東壓濾機在設計上充分考慮了維護和保養的需求,使得設備在日常使用中易于維護,降低了運營成本。

5. 節能環保:蘇東壓濾機在生產過程中注重節能環保,采用低能耗設計,同時減少廢水的排放,為綠色環保事業做出了積極貢獻。

三、蘇東壓濾機的應用領域

蘇東壓濾機以其卓越的性能和廣泛的應用領域而備受贊譽。其產品廣泛應用于以下領域:

1. 化工行業:在化工生產過程中,蘇東壓濾機可用于各種化學反應的固液分離,提高產品質量和收率。

2. 制藥行業:在制藥生產中,蘇東壓濾機用于提取、濃縮、結晶等工藝過程中的固液分離,保證藥品的純度和安全性。

3. 食品行業:蘇東壓濾機在食品加工領域中廣泛應用于果汁、果醬、乳制品等的過濾與澄清,提高食品品質和口感。

4. 環保行業:蘇東壓濾機在廢水處理、污泥脫水等領域發揮著重要作用,有效降低污染物排放,改善環境質量。

5. 其他領域:除了上述領域外,蘇東壓濾機還廣泛應用于冶金、電力、煤炭等其他工業領域,為各行業的過濾需求提供高效穩定的解決方案。

四、蘇東壓濾機的未來發展

隨著科技的不斷進步和市場需求的變化,蘇東壓濾機將繼續致力于技術創新和產品升級。未來,蘇東壓濾機的發展將重點關注以下幾個方面:

1. 智能化發展:加強智能化技術的研發與應用,提高設備的自動化和遠程控制水平,降低人工干預,提高生產效率。

2. 節能環保:持續優化設備能效,降低能耗和排放,積極響應國家綠色發展的號召,為全球環保事業做出更大貢獻。

3. 個性化定制:根據不同行業和客戶的特殊需求,提供個性化的產品定制服務,滿足市場的多樣化需求。

4. 拓展應用領域:進一步拓展蘇東壓濾機的應用領域,探索其在新能源、新材料等新興領域中的應用潛力。

5. 國際市場拓展:加強國際市場的開拓與布局,提升蘇東壓濾機在國際上的知名度和競爭力,推動中國制造走向世界。

總結來說,蘇東壓濾機作為國內壓濾機行業的佼佼者,在技術研發、產品創新、市場拓展等方面取得了顯著成果。未來,隨著智能化、節能環保等技術的發展以及應用領域的不斷拓展,蘇東壓濾機將繼續引領過濾行業的技術革新,為全球過濾需求提供更加高效、穩定、環保的解決方案。

]]>一、壓濾機的用途

壓濾機主要應用于以下領域:

1. 污水處理:在污水處理領域,壓濾機主要用于污泥脫水。經過生物反應池和沉淀池處理后的污泥,通過管道輸送到壓濾機中進行脫水。壓濾機通過施加壓力,使污泥中的水分被擠出,從而實現污泥的脫水。脫水泥餅可以進行進一步處理或利用。

2. 化工:在化工領域,壓濾機主要用于固液分離。例如,在生產硫酸、化肥等化工產品時,需要將原料中的固體物質與液體進行分離,此時可以使用壓濾機進行分離。

3. 冶金:在冶金領域,壓濾機主要用于對礦漿進行固液分離。通過壓濾機可以將礦漿中的有用礦物和廢石等固體物質進行分離,提高礦物的利用率。

4. 環保:除了上述領域外,壓濾機還廣泛應用于環保領域。例如,在處理工業廢水、城市污水等方面,可以使用壓濾機進行固液分離,使處理后的水質達到排放標準。

二、壓濾機的工作原理

壓濾機主要由進料泵、過濾網、壓緊機構和液壓系統等部分組成。其工作原理如下:

1. 進料泵將液體和固體混合物輸送到壓濾機的過濾網中。

2. 過濾網的作用是將固體物質截留在其表面,而液體則通過過濾網流出。此時,固體物質被壓縮在過濾網的表面形成濾餅。

3. 壓緊機構將過濾網室兩側的板框壓緊,以產生一定的壓力。隨著時間的推移,壓力逐漸增大,使濾餅中的水分被擠出。

4. 液壓系統是壓濾機的動力源,通過液壓油推動活塞桿和板框的運動,實現過濾和壓緊等功能。

5. 當達到預設的過濾時間或壓力時,壓濾機自動卸荷,將過濾網室兩側的板框松開。隨后,過濾網上的濾餅被刮刀刮下并排出,完成整個過濾過程。

三、壓濾機的優勢

1. 高分離效率:壓濾機采用高壓過濾技術,可以在短時間內完成大量固液混合物的分離。

2. 節能環保:相對于傳統的沉淀池和離心機等分離方法,壓濾機在運行過程中能耗較低,且產生的污泥量較少,有利于環保。

3. 自動化程度高:現代壓濾機大多采用智能控制系統,可以實現自動進料、自動控制壓力和時間等功能,減少了人工操作和提高了生產效率。

4. 應用范圍廣:由于其高效、節能和環保等特點,壓濾機在各個領域都有廣泛的應用前景。

壓濾機作為一種高效、節能的固液分離設備,在廠子里的應用十分廣泛。其工作原理主要是通過施加壓力使液體和固體混合物中的固體物質被截留在過濾網上,并形成濾餅,同時液體通過過濾網流出。經過一段時間后,壓緊機構松開,刮刀將濾餅刮下并排出,完成整個過濾過程。在污水處理、化工、冶金、環保等領域中,壓濾機都發揮著重要的作用。隨著技術的不斷進步和應用需求的增加,未來壓濾機的性能和功能將得到進一步提升和完善。

]]>一、大連壓濾機入料泵價格影響因素

大連壓濾機入料泵的價格因多種因素而異,其中主要因素包括設備型號、規格、材料、功能和廠家品牌等。

1. 設備型號與規格

不同型號和規格的大連壓濾機入料泵具有不同的性能和參數,因此價格也不同。一般來說,型號越大、規格越高的入料泵價格越高。

2. 設備材料

大連壓濾機入料泵的材料質量對其性能和使用壽命有著重要影響。優質的材料能夠提高設備的耐腐蝕性、抗壓性和穩定性,但價格也相對較高。常見的材料有不銹鋼、碳鋼等。

3. 設備功能與配置

大連壓濾機入料泵的功能和配置也是影響價格的重要因素。例如,自動控制、遠程監控、加熱保溫等功能和配置會增加設備成本,從而推高價格。

4. 廠家品牌與口碑

知名品牌和良好口碑的廠家通常能夠提供更高質量的壓濾機入料泵,但價格也相對較高。而一些小廠家或不知名品牌可能會提供價格相對較低的產品,但質量和售后可能無法保證。

二、大連壓濾機入料泵的價格范圍

根據以上因素,我們可以大致給出大連壓濾機入料泵的價格范圍:

1. 入門級:通常在10萬元以下,適用于小型企業和初創企業,性能和配置相對較低。

2. 中檔型:價格在10萬元至50萬元之間,適用于中等規模的企業和需要一定性能的場合,性能和配置相對較高。

3. 高端型:價格在50萬元以上,適用于大型企業、高要求場合或特殊用途,性能和配置非常高。

需要注意的是,以上價格僅為大致參考,實際價格還需根據具體型號、規格、材料、功能和配置進行確定。購買大連壓濾機入料泵時,建議多方比較、了解市場行情,并選擇正規、有資質的廠家進行購買,以確保質量和售后服務的可靠性。

三、如何選購合適的大連壓濾機入料泵

在選購大連壓濾機入料泵時,除了關注價格之外,還需要注意以下幾個方面:

1. 了解自身需求:根據實際生產需求和物料性質,選擇適合的型號和規格的壓濾機入料泵。例如,需要處理何種液體和固體混合物、過濾面積和過濾壓力的要求等。

2. 考察廠家實力:選擇正規、有資質的廠家進行購買,了解其生產能力、產品質量、售后服務等方面的信息。可以通過實地考察、參觀樣板工程、了解客戶評價等方式進行評估。

3. 比較不同產品:多方比較不同型號、規格、材料、功能和配置的大連壓濾機入料泵,找出性價比最高的產品。不要只看價格,也要關注質量和性能等因素。

4. 遵循安全規范:確保選購的大連壓濾機入料泵符合國家和行業安全規范,能夠安全穩定地運行,避免因設備故障或操作不當引起的安全事故。

5. 考慮長期維護與成本:除了購買成本外,還需要考慮設備的長期維護成本和使用壽命。選擇質量可靠、易于維護的設備能夠降低長期運營成本。

6. 簽訂正規合同:在購買大連壓濾機入料泵時,要與廠家簽訂正規的銷售合同,明確設備的型號、規格、質量保證、售后服務等內容,以便在后續出現問題時能夠保護自己的權益。

選購合適的大連壓濾機入料泵需要考慮多方面因素,包括價格、性能、質量、廠家實力等。只有綜合考慮這些因素,才能選擇到適合自己需求的入料泵,為企業的生產提供穩定可靠的保障。在具體選擇過程中,還需要結合企業自身實際情況進行評估和決策,以便更好地滿足實際生產需求。

]]>一、大型機械設備市場

大型機械設備市場是出售高壓圓板壓濾機的主要場所之一。這些市場通常集中了眾多的機械設備生產和銷售商家,他們為了滿足客戶的需求,會提供各種型號和規格的高壓圓板壓濾機。在這些市場購買設備,可以比較不同商家的產品性能、價格和服務,從而選擇最適合自己的設備。

二、在線電商平臺

隨著電子商務的興起,許多商家選擇在在線電商平臺上銷售高壓圓板壓濾機。通過電商平臺,客戶可以方便地瀏覽不同商家的產品,比較價格和規格,并選擇適合自己的型號。電商平臺上的商家通常提供送貨上門服務,為客戶節省了時間和精力。一些知名的在線電商平臺如阿里巴巴、京東等都有出售高壓圓板壓濾機的商家。

三、廠家直銷

除了市場和電商平臺外,直接從廠家購買也是獲取高壓圓板壓濾機的一種方式。有些廠家為了拓展銷售渠道,會設立直銷部門或通過網絡營銷的方式直接與客戶建立聯系。從廠家直接購買可以避免中間商的環節,獲得更優惠的價格。與廠家直接溝通還能更好地了解設備的生產過程和工藝,有助于客戶更好地選擇和使用設備。

四、二手市場

在二手市場也有可能出現高壓圓板壓濾機的身影。一些企業或個人由于更新設備或資金問題,會將之前使用過的設備進行出售。雖然二手市場上的設備可能存在一定的磨損或老化情況,但價格相對較低,對于一些預算有限的客戶來說是一個不錯的選擇。在二手市場購買時,建議客戶仔細檢查設備的性能和狀況,確保其滿足自己的使用要求。

五、展會和展覽會

展會和展覽會是展示各類機械設備的場所,高壓圓板壓濾機也會在這些活動中得到展示和銷售。在這些展覽會上,客戶可以親眼看到設備的實物,了解其外觀和性能,同時還能與生產商直接交流,獲取更多的產品信息和使用建議。通過展會和展覽會購買設備,可以更全面地了解市場上的產品和技術動態。

高壓圓板壓濾機可以在大型機械設備市場、在線電商平臺、廠家直銷、二手市場以及展會和展覽會上購買。客戶可以根據自己的需求和實際情況選擇最適合的購買方式。在購買過程中,建議客戶仔細了解產品的性能、價格和服務,確保自己獲得滿意的產品和服務。也建議客戶選擇有信譽的商家和廠家進行購買,以保障自己的權益。

]]>一、影響250平壓濾機重量的因素

1. 制造材料:250平壓濾機的制造材料對其重量有著顯著的影響。例如,采用高強度鋼材、鑄鐵等材料制造的壓濾機通常會更重。而采用輕質材料如鋁合金等制造的壓濾機則會相對較輕。

2. 結構形式:250平壓濾機的結構形式也會對其重量產生影響。一般來說,板框式壓濾機的重量相對較輕,而廂式壓濾機的重量則相對較重。壓濾機的內部結構,如濾板、濾框等的設計和排列也會對其重量產生影響。

3. 制造工藝:250平壓濾機的制造工藝對其重量也有影響。先進的制造工藝和設備可以保證壓濾機的高精度和高質量,但同時也可能導致重量增加。相反,傳統的制造工藝和設備可能導致重量減少。

4. 附件和功能:250平壓濾機所配備的附件和功能也會對其重量產生影響。例如,帶有自動控制系統、液壓系統等附件的壓濾機通常會更重。而只具備基本功能的壓濾機則相對較輕。

二、如何確定250平壓濾機的重量

1. 查看產品說明:在購買或選擇250平壓濾機時,應仔細閱讀產品說明,了解其重量的具體數值。產品說明通常會提供有關壓濾機的詳細信息,包括其重量、尺寸、性能參數等。

2. 咨詢制造商:如果產品說明中未提供250平壓濾機的重量信息,可以聯系制造商或供應商咨詢其重量。制造商或供應商會根據其產品特點和設計提供準確的重量數據。

3. 實際測量:如果無法獲得產品說明或制造商的重量信息,還可以通過實際測量來確定250平壓濾機的重量。可以使用合適的稱重設備或測量工具來稱量壓濾機的重量,以獲得準確的數值。

要準確了解250平壓濾機的重量,應考慮其制造材料、結構形式、制造工藝、附件和功能等因素。通過仔細閱讀產品說明、咨詢制造商或進行實際測量,可以獲得準確的重量數據。了解250平壓濾機的重量對于評估其性能、運輸和安裝成本等方面具有重要意義。在選擇和使用250平壓濾機時,還應注意其使用環境和工況條件,以確保其正常運行和使用壽命。

]]>一、實驗型壓濾機的設計初衷

在實驗室過濾實驗中,研究人員需要一種能夠快速、準確地測試和驗證過濾工藝的設備。傳統的工業壓濾機雖然能夠實現過濾功能,但其設計、結構和工作原理相對較為復雜,操作和維護需要專業人員。工業壓濾機通常無法根據實驗需求進行靈活調整,不能滿足多種實驗條件下的過濾需求。因此,設計實驗型壓濾機的初衷是為了解決實驗室過濾實驗中的這些問題,提供一種簡單、高效、靈活的過濾設備。

二、實驗型壓濾機的優勢

1. 靈活性高:實驗型壓濾機可根據實驗需求進行定制和調整,包括濾板尺寸、過濾面積、過濾壓力等。這種靈活性使得實驗型壓濾機能夠適應不同實驗條件下的過濾需求,提高實驗效率和效果。

2. 操作簡便:實驗型壓濾機的結構簡單,操作方便。研究人員可以輕松地安裝和拆卸濾板、濾布等部件,無需專業人員協助。實驗型壓濾機通常配備智能控制系統,可實現自動化操作,進一步簡化操作流程。

3. 快速高效:實驗型壓濾機采用高效的過濾元件和材料,能夠快速完成過濾過程。由于其結構緊湊,占地面積小,可有效節省實驗室空間。

4. 降低成本:與工業壓濾機相比,實驗型壓濾機的制造成本較低。由于其結構簡單、維護方便,使用成本也相對較低。這有助于降低實驗室過濾實驗的成本,提高實驗的經濟效益。

5. 可靠性高:實驗型壓濾機采用高品質的材料和零部件制造而成,經過嚴格的質量控制和測試,具有較高的可靠性和穩定性。這有助于保證實驗結果的準確性和可靠性。

三、實驗型壓濾機的應用價值

1. 科研領域:在科研領域中,實驗型壓濾機廣泛應用于各種過濾實驗,如固液分離、氣液分離、化學反應等。通過使用實驗型壓濾機,研究人員可以快速、準確地測試和驗證各種過濾工藝和技術,為科研工作提供有力支持。

2. 教學領域:在高校和培訓機構中,實驗型壓濾機可用于過濾實驗教學。通過實際操作和實驗演示,學生可以深入了解過濾原理、設備結構和操作方法等方面知識,提高教學質量和效果。

3. 產品開發:在產品開發過程中,實驗型壓濾機可用于測試和驗證新產品的性能和效果。通過模擬實際使用條件下的過濾過程,研究人員可以評估產品的性能指標和可行性,為產品開發提供重要依據。

4. 質量檢測:在生產過程中,實驗型壓濾機可用于質量檢測和控制。通過定期對產品進行過濾實驗,可以檢測產品的質量和穩定性,及時發現并解決潛在問題,提高產品質量和生產效率。

5. 環保領域:在環保領域中,實驗型壓濾機可用于處理各種工業廢水、廢氣等污染物。通過實驗研究和實踐應用,研究人員可以探索有效的過濾技術和工藝,為環保事業提供技術支持和解決方案。

實驗型壓濾機作為一種專為實驗室過濾實驗而設計的設備,具有靈活性高、操作簡便、快速高效、降低成本和可靠性高等優勢。在實際應用中,實驗型壓濾機在科研、教學、產品開發、質量檢測和環保等領域發揮著重要作用,為相關領域的發展提供有力支持。隨著科學技術的不斷進步和創新需求的不斷增加,實驗型壓濾機的應用前景將更加廣闊。

]]>一、六安二手壓濾機市場概述

六安地區的二手壓濾機市場相對較為活躍,主要來源于以下幾個渠道:一是企業淘汰的舊設備;二是閑置的設備;三是部分企業因為資金鏈斷裂等原因低價出售的設備。這些設備雖然已經使用過一段時間,但由于經過了嚴格的保養和維護,性能和使用壽命仍可得到保證。因此,對于那些需要節省成本的企業而言,購買二手壓濾機是一個不錯的選擇。

二、六安二手壓濾機的價格因素

1. 型號與規格

不同型號和規格的二手壓濾機價格存在差異。一般來說,大型號的二手壓濾機價格較高,但處理能力也更強。而小型號的二手壓濾機價格相對較低,適用于處理量較小的場所。因此,在選擇二手壓濾機時,應根據實際需求選擇合適的型號和規格。

2. 品牌與服務

知名品牌的二手壓濾機價格相對較高,但品質有保障,性能穩定可靠。而一些不知名品牌的二手壓濾機價格可能會低一些,但品質和性能可能存在不確定性。廠家的售后服務也是影響二手壓濾機價格的重要因素。良好的售后服務可以保證設備的長期穩定運行,并為用戶提供更加便捷的維修和保養服務。因此,在選擇二手壓濾機時,應根據廠家的品牌和服務進行綜合考慮。

3. 設備狀況

二手壓濾機的價格還與其設備狀況有關。如果設備保養得當,外觀和性能良好,其價格自然會相對較高。反之,如果設備存在磨損、老化等問題,或者保養不當導致性能下降,其價格就會相應降低。因此,在購買二手壓濾機時,建議先對設備進行全面的檢查和評估,以了解其真實狀況。

4. 市場供求關系

六安二手壓濾機的價格還受到市場供求關系的影響。如果市場上二手壓濾機供應不足,其價格自然會相應升高。反之,如果市場上存在大量閑置或淘汰的二手壓濾機,其價格就會相應降低。因此,在購買二手壓濾機時,建議多了解市場行情,以便更好地把握時機。

三、如何選擇合適的六安二手壓濾機

1. 根據實際需求選擇合適的型號和規格

在選擇六安二手壓濾機時,應根據實際需求選擇合適的型號和規格。根據處理能力、污泥性質等參數選擇合適型號的二手壓濾機,確保設備的性能滿足生產要求。還要考慮設備的尺寸和安裝空間等因素,以確保設備的適用性和靈活性。

2. 注重品質與性能

在選擇六安二手壓濾機時,應注重其品質與性能的選擇。用戶應選擇品質優良、性能穩定可靠的二手壓濾機,以提高設備的可靠性和使用壽命。還要考慮設備的安全性能和防護措施等方面的問題,以確保設備的安全性和穩定性。

3. 考慮功能與配置的必要性

根據實際需求選擇具備合適功能和配置的二手壓濾機,可以提高生產效率和質量。例如:如果需要自動化控制系統來控制二手壓濾機的運行,可以選擇配備該系統的設備;如果需要智能監控來實時監測設備的運行狀態,可以選擇具備該功能的設備。但需要注意的是,不要選擇過于高端的設備,以免造成不必要的浪費。還要了解功能擴展性和升級性等方面的問題,以滿足未來生產的需求變化。

4. 參考市場價格與行情

在選擇六安二手壓濾機時,應參考市場價格與行情,避免選擇價格過高或過低的設備。還需要注意供應商的信譽和服務質量等方面的問題。建議選擇具有良好口碑和售后服務的大型二手壓濾機供應商,以確保購買到高品質的設備并獲得周到的售后服務。還要注意設備的性價比和投資回報等方面的問題,以滿足設備的經濟性和可行性。

]]>